Distribution channels must communicate to farmers where to return empty crop protection packages

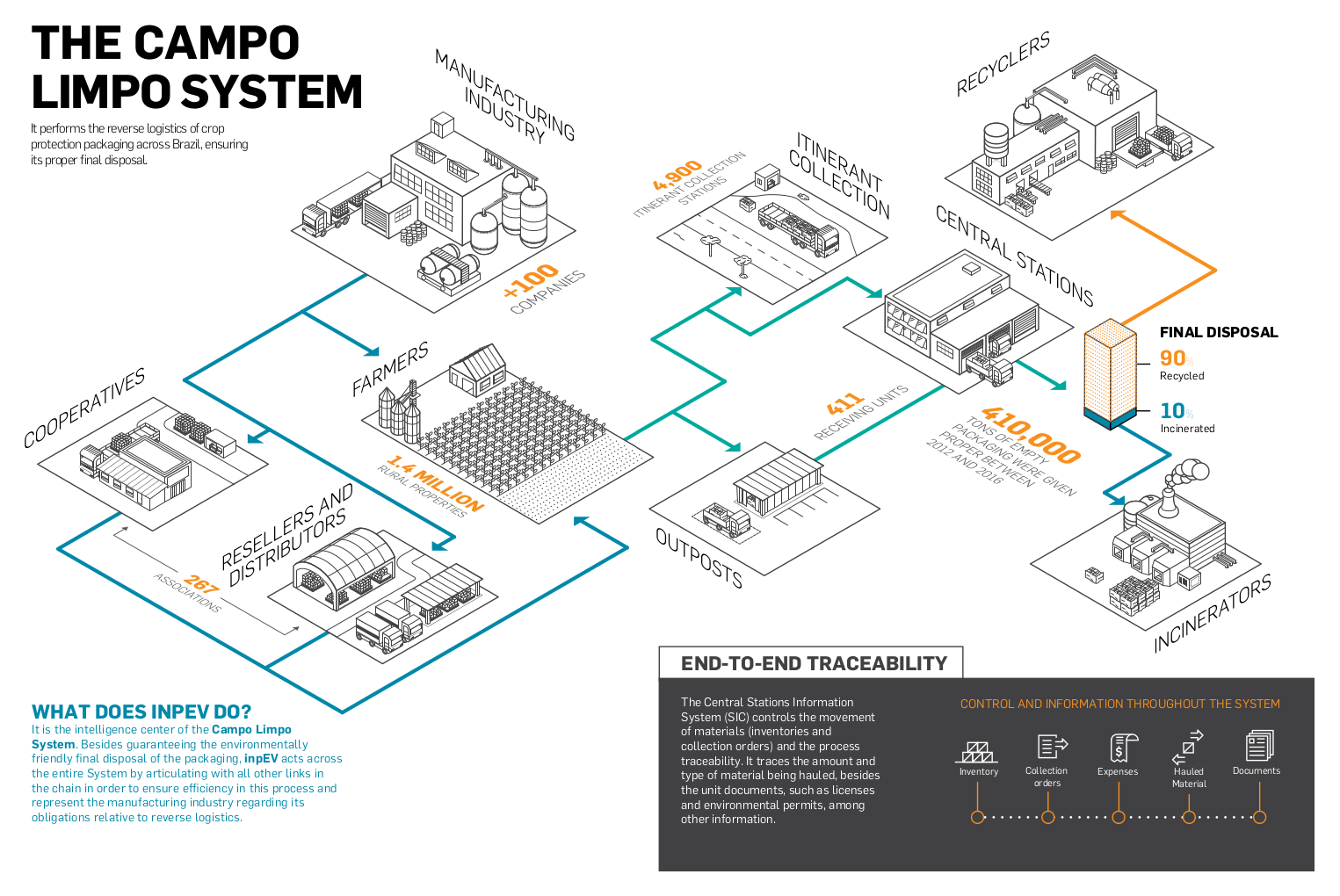

The Campo Limpo System

Shared responsibilities: each link in the chain does its part

The Campo Limpo System expresses the concern of the entire chain regarding sustainability of agricultural activities and conservation of the environment.

Stated in Law 9.974/00, the concept of shared responsibility identifies the role of each member in the proper disposal of empty crop protection packaging. Responsible for the results of the System, the links of the chain are the farmers, distributors and co-operatives, industry (represented by inpEV), and the public power.

This commitment ensures that 94% of primary packaging (in contact with the product) marketed from year to year are correctly disposed of, which makes Brazil the greatest world reference in the management of these materials.

In 2016, the System reached another milestone, when it surpassed 400,000 tons of empty packages disposed of in an environmentally correct fashion – since the beginning of its operation in 2002, totaling 410,000 tons.

“A fundamental point for inpEV's success is the relationship among all links in the agricultural chain. This integrating attitude is one of the values and a key practice of inpEV. The responsibility that each one undertakes is clearly seen and it is amazing how it makes a difference!”

Antônio Carlos do Amaral, North and Northeast Operations Manager, with inpEV since 2005

Receiving units

The Campo Limpo System has 411 receiving units throughout the country. Divided into central stations and outposts, these spaces are managed by associations of crop protection distributors, except for the five central stations managed by inpEV.

The distribution channel of crop protection products is responsible for managing these units. inpEV seeks to guide and disseminate good practices on topics such as labor practices, safety and financial administration, though it is not responsible for managing these units.

Both the outposts as well as the central receiving stations meet the requirements of CONAMA resolution 465/14 as to environmental licensing and carry out the following activities:

- Receipt of washed and unwashed packages

- Inspection and classification of washed and unwashed packaging;

- Issuance of a receipt confirming delivery of the packages;

- Separation per type of packaging (COEX, MONO HDPE, metal, cardboard);

- Packaging compacting per type of material (only receiving stations);

- Issuance of a collection order so that inpEV provide the transportation to the final destination (recycling or incineration) (only central stations).

A series of initiatives have contributed to ensure a safe working environment at the SCL units. Among them, the implementation of a logistics checklist, launched in 2015 and expanded over the past year, in which central receiving station drivers and operators use a packaging loading checklist containing preventive safety requirements. In another improvement adopted in 2016, inpEV professionals and a specialized provider developed a new tool that will contribute towards operator safety at the central stations: a deburring tool especially designed to assist in removing seals and labels, opening boxes or plastic pouches, replacing and standardizing the different types of cutting tools adopted previously. The need to improve this step was identified during the accident and incident indicator analysis of the central stations. This specific tool is properly sized, having adequate functionality and a reduced blade area size, among other aspects. After a series of tests, this equipment will be made available and may be adopted at all plants starting in 2017.

Safety is also a recurring topic at the meetings promoted by the inpEV Operations management with the central station managers. The meetings are held at least twice a year, divided by regions, and focus on strategic alignment and strengthening the actions of the System. Despite all efforts, in 2016 there was a 3% increase in accidents recorded at the 411 units – which represents one case more than in the previous year. In the units managed by inpEV, the accident rate was zero. It is worth mentioning that the System did not record any fatal accidents during these 15 years.

Safety

In 15 years, SCL did not record any fatal accidents

Quality management

Also with the intent of assisting central station managers in gaining efficiency and adopting good practices, inpEV implemented a program with the purpose of revising the quality of adopted processes. With the aid of a consulting firm, the analysis included administrative, legislation, safety, and environmental management issues, among others. In 2016, the third and final year of the project, 93 central stations were evaluated, 40 of which in person. Each central station received a diagnosis of its unit, which will help manage the continuous improvement process.

This program is also part of inpEV's efforts to improve the management of the receiving units by offering relevant benefits to the entire Campo Limpo System. A manual containing guidelines on the processes of selection, admission, discharge, and job descriptions, among other topics, was made available to the managers of these units, aiming at standardizing processes and replicating best practices.

Each and everyone's responsibility

As determined by law, the concept of shared responsibility defines what each chain link is accountable for:

Farmers

Perform the triple rinse, void and return the empty package

Distribution Channels

Inform the return location on the bill of sale, maintain the receiving locations and receive the Empty Packaging (EVs) Education and awareness

Manufacturers

Final disposal and logistics

Education and awareness

Public power

Supervise, provide guidelines and license the operation of the receiving units. Also supports the education and awareness actions

New frontiers

inpEV follows the growth of agricultural production and seeks to adjust the structure of the Campo Limpo System to ensure its capillarity. The so-called new frontiers, especially those known as Matopiba, formed by the states of Maranhão, Tocantins, Piauí and Bahia, have new receiving units that were inaugurated in recent years. In 2016, the network expanded to other regions as a result of the growing demand in the country, with the inauguration of two empty packaging receiving outposts in Paraúna and Formosa, Goiás, and an outpost in the town of Redenção, in Pará.

inpEV Central Stations

In 2016, two new central stations started being managed by inpEV, totaling five receiving units under direct coordination. This integration generates knowledge and approaches the inpEV professionals to the reality of the plants. The purpose is for these central stations to host training courses for the employees of the units in their regions and for them also to become a reference for innovation and dissemination of good practices.

The two new inpEV central stations are Boa Vista do Incra (RS) and Unaí (MG), which previously worked under the management of dealer associations and a cooperative, respectively. These units add up to those of Alto Parnaíba (MA), Rondonópolis (MT) and Taubaté (SP).

Innovation & technology

Innovation is present at inpEV since the beginning of its activities, when it designed a unique reverse logistics system for empty crop protection packaging. To innovate means to define strategies, create new paths and bring improvements to its processes, in order to gain efficiency and expand the footprint of the Campo Limpo System.

To think through the challenges of upcoming years in a mid to long-term horizon, inpEV will develop the Station of the Future project starting in 2017. To understand the type of construction that can generate more efficiency and new technologies for more rational use of water and energy, for example, are part of this study. The purpose is to be attentive to innovations and increase safety and compliance with environmental issues. The current central stations will also provide their contribution, by evaluating and sharing best practices that can be replicated. The project intends to follow the developments of agriculture and crop protection, and conceive the most appropriate system for the future.

In 2016, inpEV professionals, in conjunction with partnering consultancies, have also developed a prototype of a new press to compact packaging. With a capacity three times greater than the machines currently used at the central stations, this technology is undergoing final evaluations that will define its feasibility for the System.

Fundamentals of the Campo Limpo System

Legislation

Defines specific responsibilities for each link of the agricultural chain

Integration

Involvement of all the links since the beginning of the System

Education and awareness

Continuous and consistent efforts

Processes and information management

Offers support to decision-making with emphasis on increased productivity, efficiency, generation and capture of value.